applications

Coating

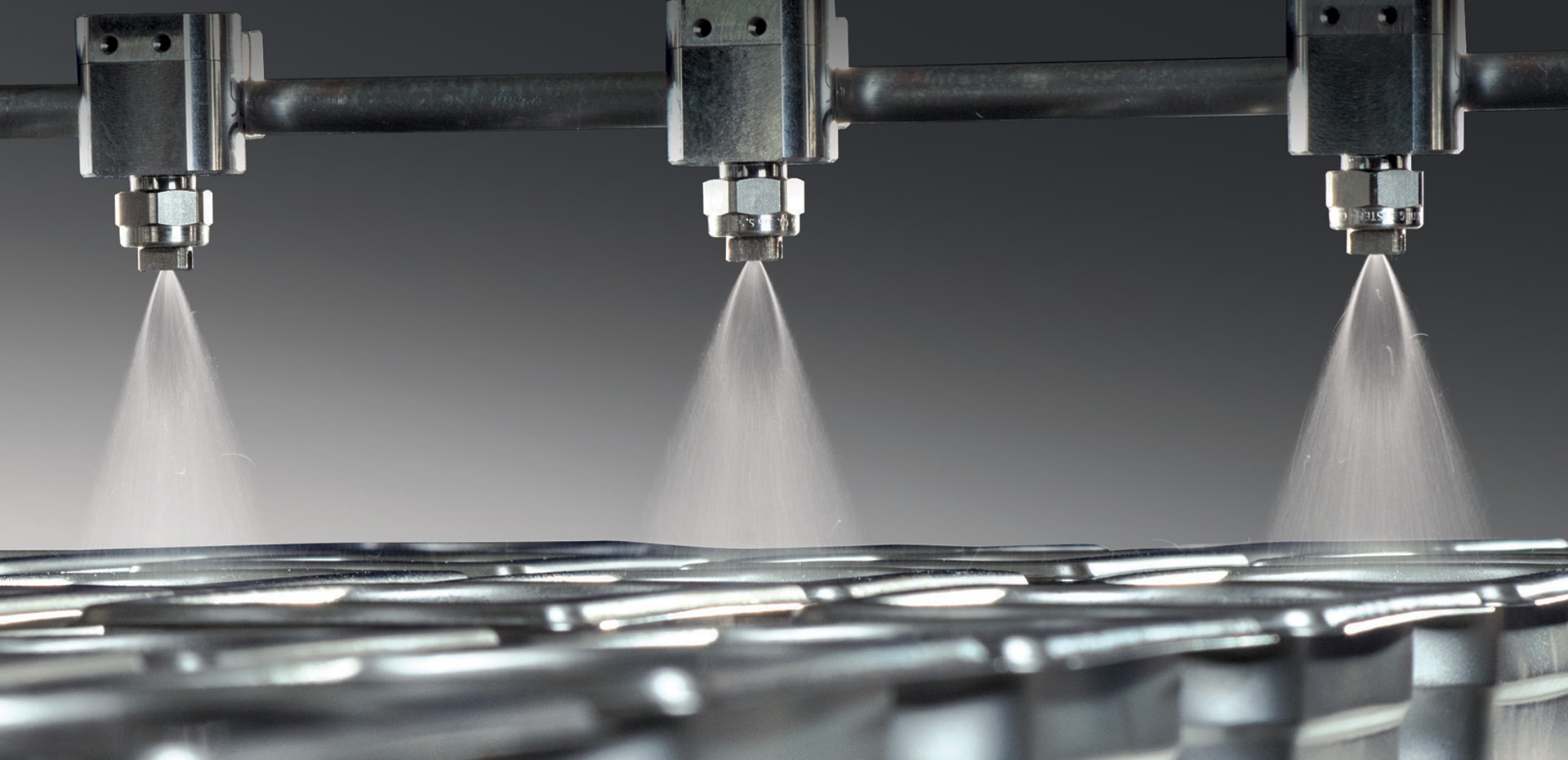

If you experience quality problems caused by uneven coatings or waste costly coatings due to over-application, consider coating solutions from Spraying Systems Co. Our wide range of nozzles, standard and heated spray headers, and automated spray systems ensure uniform, efficient application of all types of coatings for a variety of industries.